English

English-

English

English -

Español

Español -

Português

Português -

русский

русский -

Français

Français -

日本語

日本語 -

Deutsch

Deutsch -

tiếng Việt

tiếng Việt -

Italiano

Italiano -

Nederlands

Nederlands -

ภาษาไทย

ภาษาไทย -

Polski

Polski -

한국어

한국어 -

Svenska

Svenska -

magyar

magyar -

Malay

Malay -

বাংলা ভাষার

বাংলা ভাষার -

Dansk

Dansk -

Suomi

Suomi -

हिन्दी

हिन्दी -

Pilipino

Pilipino -

Türkçe

Türkçe -

Gaeilge

Gaeilge -

العربية

العربية -

Indonesia

Indonesia -

Norsk

Norsk -

تمل

تمل -

český

český -

ελληνικά

ελληνικά -

український

український -

Javanese

Javanese -

فارسی

فارسی -

தமிழ்

தமிழ் -

తెలుగు

తెలుగు -

नेपाली

नेपाली -

Burmese

Burmese -

български

български -

ລາວ

ລາວ -

Latine

Latine -

Қазақша

Қазақша -

Euskal

Euskal -

Azərbaycan

Azərbaycan -

Slovenský jazyk

Slovenský jazyk -

Македонски

Македонски -

Lietuvos

Lietuvos -

Eesti Keel

Eesti Keel -

Română

Română -

Slovenski

Slovenski -

मराठी

मराठी -

Srpski језик

Srpski језик

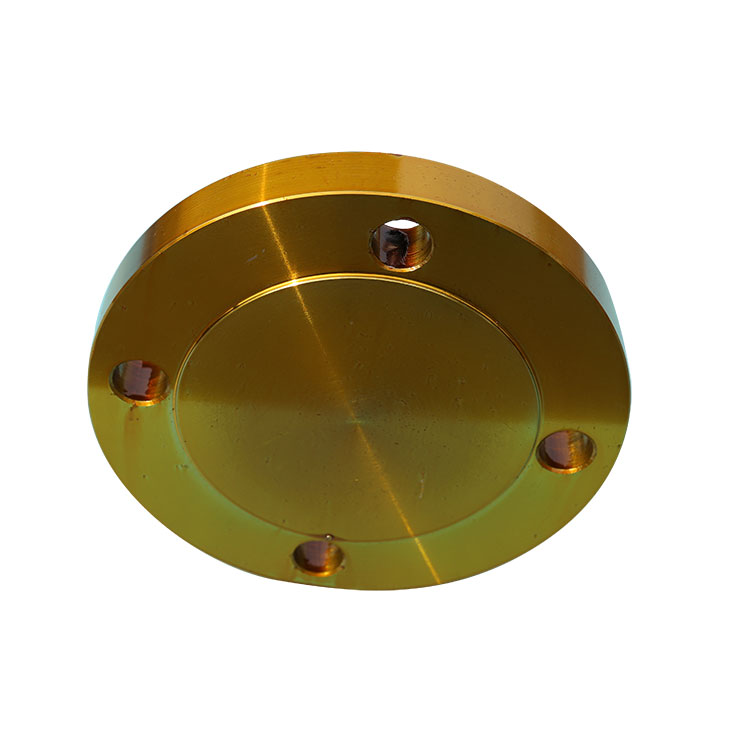

Blind Flange: The Key "Safety Shield" In the Pipeline System

2025-07-25

In the complex industrial pipeline network, there is a seemingly simple but crucial component that is silently guarding the safety and efficiency of the system - it is the Blind Flange. As the core sealing element in pipeline engineering, the blind flange has become the behind-the-scenes hero to ensure the reliable operation of various fluid conveying systems with its unique design and function.

Core role: excellent sealing and safe isolation

The core value of the blind flange lies in its strong sealing and isolation capabilities. Unlike the flange with holes, it uses a completely closed solid disk surface and can withstand high pressure (common pressure rating of more than 16MPa), playing a key role in pipeline system maintenance, isolation of unused branches or plugging of pipes. Whether it is the emergency shutdown of a chemical plant, the section-by-section maintenance of an oil refining unit, or the pressure test of a new pipeline, as long as a blind flange that meets the specifications is used, it can block the flow of the medium like a "shield", effectively prevent leakage and energy loss, and build a solid line of defense for personnel safety and environmental protection.

Outstanding features: strong and durable, flexible and efficient

The core features of Blind Flange are concentrated in the sturdiness of its structure and the flexibility of its application:

High strength and pressure resistance

Made of high-quality forged carbon steel, stainless steel or special alloys, it ensures long-term stable service in high temperature, high pressure and corrosive environments.

Standardized installation: It follows international standards (such as ASME, DIN), has a full range of sizes (covering DN15 to DN2400), can be paired with universal flanges, and can be installed or disassembled by bolting only, greatly shortening the equipment downtime.

Safe and convenient: The flat and smooth sealing surface is matched with standard gaskets to achieve zero leakage sealing; its eye-catching shape (usually a full circle or an "8" shape with a handle) makes it easy to identify the operating status and significantly reduces the risk of misoperation.

As the world's requirements for industrial safety and environmental protection become increasingly stringent, Blind Flange, as a standardized tool for pipeline safety management, is increasingly valued for its standardized use. Industry experts emphasize that correct selection, installation according to regulations and regular inspection are the key to the effectiveness of blind flanges. This seemingly simple component will continue to protect the pulse of modern industrial pipelines and ensure safe production with its reliable sealing and isolation performance.