English

English-

English

English -

Español

Español -

Português

Português -

русский

русский -

Français

Français -

日本語

日本語 -

Deutsch

Deutsch -

tiếng Việt

tiếng Việt -

Italiano

Italiano -

Nederlands

Nederlands -

ภาษาไทย

ภาษาไทย -

Polski

Polski -

한국어

한국어 -

Svenska

Svenska -

magyar

magyar -

Malay

Malay -

বাংলা ভাষার

বাংলা ভাষার -

Dansk

Dansk -

Suomi

Suomi -

हिन्दी

हिन्दी -

Pilipino

Pilipino -

Türkçe

Türkçe -

Gaeilge

Gaeilge -

العربية

العربية -

Indonesia

Indonesia -

Norsk

Norsk -

تمل

تمل -

český

český -

ελληνικά

ελληνικά -

український

український -

Javanese

Javanese -

فارسی

فارسی -

தமிழ்

தமிழ் -

తెలుగు

తెలుగు -

नेपाली

नेपाली -

Burmese

Burmese -

български

български -

ລາວ

ລາວ -

Latine

Latine -

Қазақша

Қазақша -

Euskal

Euskal -

Azərbaycan

Azərbaycan -

Slovenský jazyk

Slovenský jazyk -

Македонски

Македонски -

Lietuvos

Lietuvos -

Eesti Keel

Eesti Keel -

Română

Română -

Slovenski

Slovenski -

मराठी

मराठी -

Srpski језик

Srpski језик

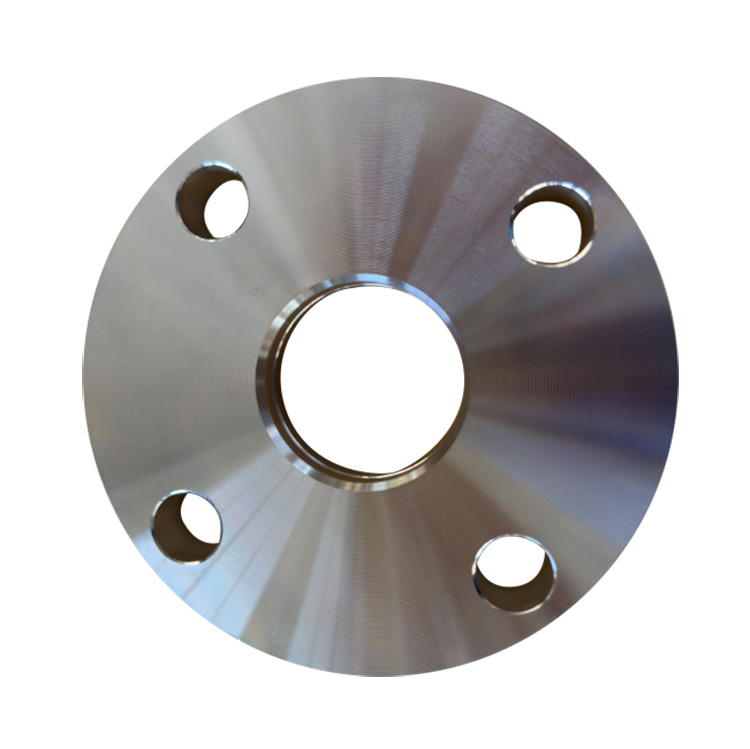

What are the reasons for the price difference of stainless steel flanges?

2025-03-22

The different management modes of stainless steel flange manufacturers result in different costs: different management modes of companies, everyone will think that it is nothing more than cutting, production, and turning, and there will be no difference. Have you ever thought that the flange needs to be tested after production to achieve the delivery status of the flange as required by the customer, but the labor cost, equipment cost, and scrap rate of the test are directly saved by some manufacturers.

Different production processes of stainless steel flanges: At present, the production processes of stainless steel flanges are divided into steel plate gas cutting flanges, steel plate splicing flanges, steel plate rolling flanges, forged flanges, and long and high diameter flanges spliced with flanges and cylinders. Among them, the raw material cost and cost of forged flanges are the highest.

Different management modes of stainless steel flange manufacturers result in different costs: different management modes of companies, everyone will think that it is nothing more than cutting, production, and turning, and there will be no difference. Have you ever thought about that the flange needs to be tested after production to ensure that the flange is delivered in the state required by the customer? However, some manufacturers directly save on the labor costs, equipment costs, and scrap rate involved in the testing.